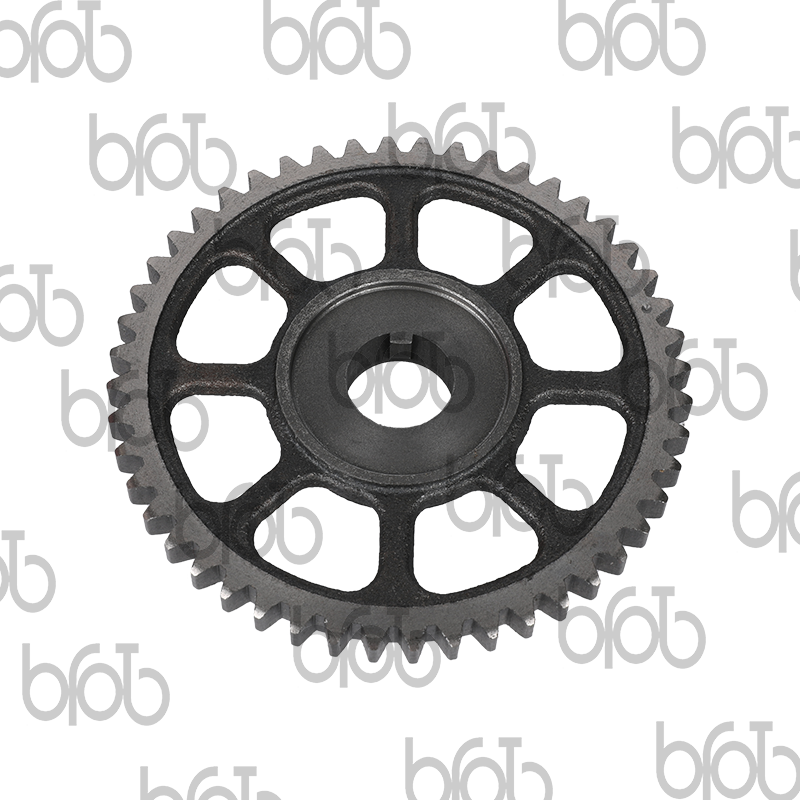

When it comes to engine performance, the crankshaft gear plays a crucial role in synchronizing the engine's timing system. Over time, wear and improper maintenance can lead to Ford crankshaft gear timing issues, unusual noises, or incorrect torque application. In this guide, we'll explore these common problems and provide solutions to keep your engine running smoothly.

Ford Crankshaft Gear Timing Issues

One of the most frequent concerns with crankshaft gears is timing misalignment, which can cause poor engine performance, misfires, or even severe internal damage. Symptoms include:

Check engine light (often with timing-related codes)

Hard starting or stalling

Reduced fuel efficiency

Causes & Fixes:

Worn timing components – Replace the gear and timing chain/belt if slack is detected.

Improper installation – Ensure correct alignment with camshaft gears during reassembly.

Oil starvation – Low oil pressure can accelerate gear wear; check lubrication system health.

Ford Crankshaft Gear Noise

A whining, rattling, or grinding noise from the engine's front often points to crankshaft gear problems. Common culprits include:

Loose or damaged gear teeth – Metal-on-metal sounds signal immediate replacement.

Failed harmonic balancer – A wobbling balancer can stress the gear, causing noise.

Timing chain tensioner failure – Allows excessive movement, leading to gear chatter.

Diagnosis Tips:

Use a mechanic's stethoscope to pinpoint noise location.

Inspect for metal shavings in oil (indicative of gear wear).

Ford Crankshaft Gear Torque Specs

Proper torque application ensures the crankshaft gear stays securely fastened. Incorrect torque can lead to:

Gear slippage (disrupting timing)

Bolt failure (catastrophic engine damage)

Recommended Torque Values (general guidelines, verify with service manual):

Crankshaft bolt: 70–100 ft-lbs (varies by model, some require angular tightening).

Timing gear bolts: 15–25 ft-lbs (use thread locker if specified).

Pro Tip: Always replace the crankshaft bolt if it's a TTY (Torque-To-Yield) design—reusing it risks failure.

English

English Español

Español Deutsch

Deutsch