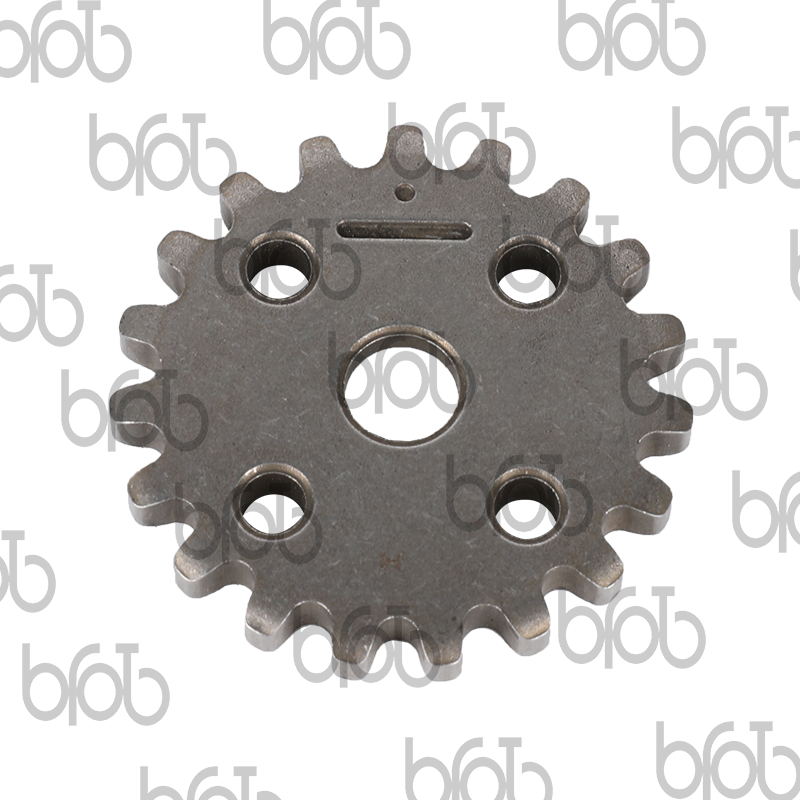

Custom Camshaft Gear

About Us

From The Blog

Provide you with the latest enterprise and industry news

-

Tips - Apr 03, 2025

Are timing chain failures common in BMW MINI?

Some BMW MINI models (especially those equipped with N14/N18 engines) are at risk of timing chain failure, but not all models or years are frequent. The failure rate is closely related to the engine m...

Read more -

Tips - Mar 27, 2025

What are the common causes of camshaft gear failure?

Camshaft gear failure is one of the common engine problems, which may cause engine performance degradation, abnormal noise or even engine failure. The following are common causes of camshaft gear fail...

Read more -

Tips - Mar 20, 2025

What are the applications of high-performance oil pump gears in the automotive industry?

High-performance oil pump gears are widely used in the automotive industry. They are key components of the engine lubrication system and play a vital role in the performance, efficiency and reliabilit...

Read more -

Tips - Mar 13, 2025

How Engine Oil Pump Sprocket Upgrades Boost Fuel Efficiency in Modern Vehicles?

1. Improved Sprocket Design for Reduced FrictionOne of the primary ways in which engine oil pump sprockets boost fuel efficiency is through reduced friction. Traditional sprockets often suffer from hi...

Read more -

Tips - Mar 06, 2025

Improved durability of engine oil pump sprocket: Combination of new materials and manufacturing processes

As a key component of automobile engines, the performance and durability of engine oil pump sprockets directly affect the efficiency and service life of the engine. In recent years, with the continuou...

Read more -

Tips - Feb 27, 2025

Requirements for crankshaft sprockets in inline engines

I. Material selectionAs an important component of the engine, the material of the Engine Timing Crankshaft Sprocket needs to have high strength, high wear resistance and good fatigue resistance. Usual...

Read more

English

English Español

Español Deutsch

Deutsch