1. Preparation work

Before starting the installation, sufficient preparations need to be made. First, make sure your work area is clean and well-lit for easy operation. Secondly, prepare the required tools and materials, including oil pump sprockets, special tools, screwdrivers, wrenches, cleaners, oil, etc. At the same time, read the official Land Rover maintenance manual carefully to understand the specific structure, installation position and calibration requirements of the oil pump sprocket. Ensure that the working environment is safe and tidy. Installation work needs to be carried out in a bright, spacious and well-ventilated environment. Make sure the work area is clean and tidy to prevent dust, debris or other potential contaminants from getting inside the engine. Additionally, wear appropriate work clothing and safety equipment, such as gloves and goggles, to protect yourself from injury. Before installing the sprocket, check the overall condition of the engine. Check the engine for signs of leaks, damage or unusual wear. If any potential problems are discovered, these should be addressed before proceeding with sprocket installation. It is also important to understand the role of the oil pump sprocket in the engine and its relationship to other engine components. This helps to better judge the position and angle of the sprocket during the installation process, ensuring the accuracy and reliability of installation.

2. Disassemble the old sprocket

When removing the old sprocket, be particularly careful not to damage other parts of the engine. First, disconnect the circuits and pipes related to the oil pump, and then use a special tool to remove the sprocket fixing screw. During the disassembly process, shake the sprocket gently to gradually separate it from the engine to avoid damage caused by sudden falling off.

3. Cleaning and Inspection

After removing the old sprocket, thoroughly clean the relevant parts of the engine. Use detergent to remove oil and impurities and ensure the installation surface is clean and free of foreign matter. At the same time, check whether the mounting surfaces of the oil pump and sprocket are worn or damaged, and replace relevant parts in time if necessary.

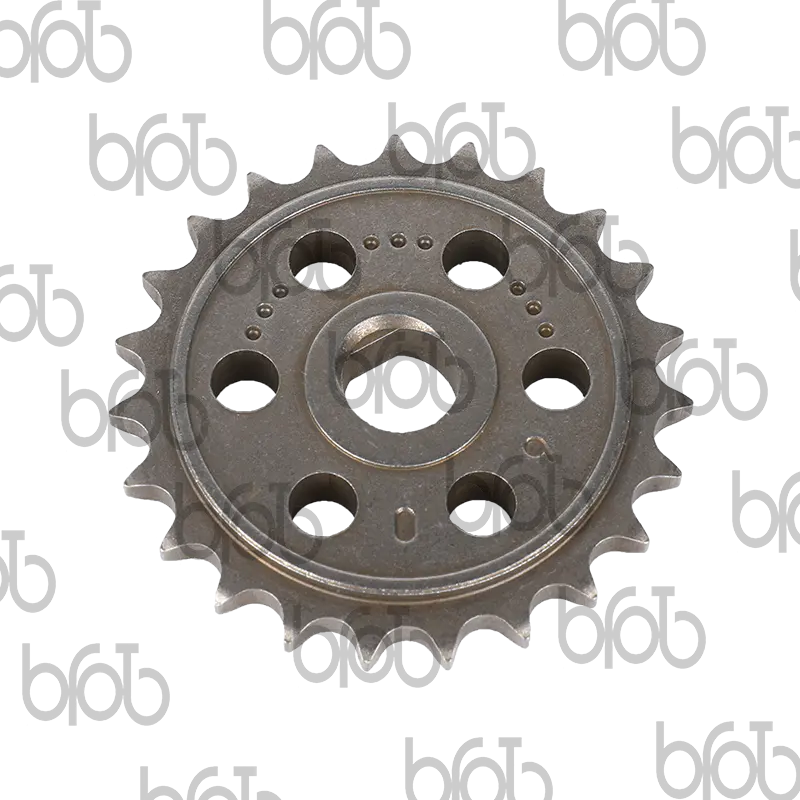

4. Install new sprocket

When installing a new sprocket, strictly follow the instructions in the official service manual. First, align the new sprocket with the oil pump, making sure it is installed correctly. Then, use a special tool to tighten the sprocket fixing screw with moderate attention to avoid being too tight or too loose. During the process of tightening the screws, constantly check the position of the sprocket to ensure that it is always in the correct state.

5. Calibration and adjustment

After installing the new sprocket, calibration and adjustment work is required. First, check whether the sprocket rotates flexibly and whether there is any jamming. The sprocket is then calibrated using special tools to ensure it fits accurately with the rest of the engine. During the calibration process, pay attention to the rotation of the sprocket and adjust the calibration parameters in time until the best state is achieved.

6. Add engine oil and test run

After completing the calibration and adjustment, you need to add an appropriate amount of engine oil to ensure that the oil pump can work properly. When adding engine oil, be sure to choose an engine oil brand and model that meets Land Rover's requirements to avoid using unsuitable engine oil and causing damage to the engine. After adding the oil, start the engine for a test run. During the trial operation, the working condition of the oil pump sprocket should be closely observed to ensure that it runs smoothly and has no abnormal noise.

7. Finishing work

After the test run, the engine should be fully inspected to ensure that all components are in normal condition. Then, clean the work area and organize tools and materials. Finally, record the detailed process and related data of this installation and calibration for future reference.

English

English Español

Español Deutsch

Deutsch